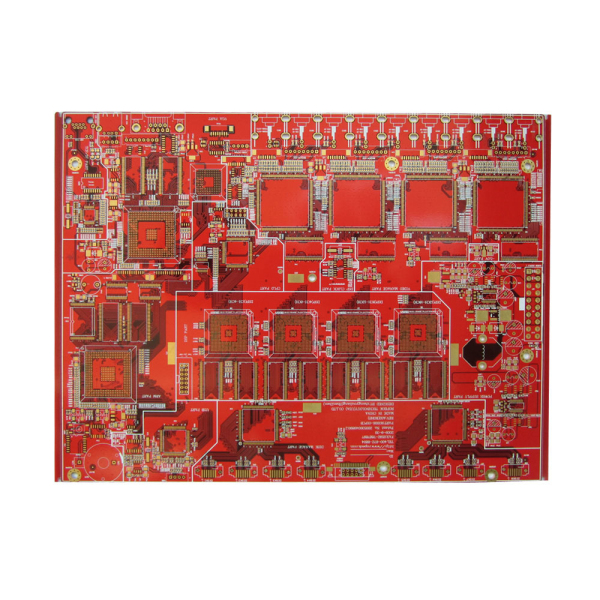

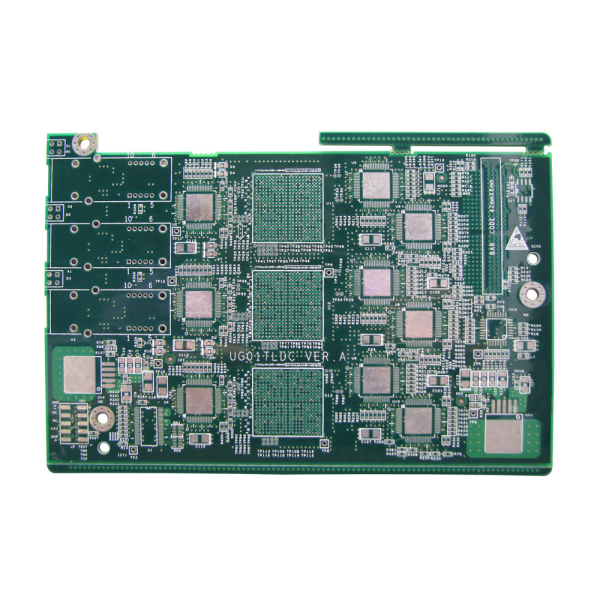

TG 170 FR4 Immersion Gold PCB Medical Equipment

| Unit Price: | 120 USD |

|---|---|

| Min. Order: | 1 Piece/Pieces |

Basic Info

Model No.: High TG 170 PCBA Medical Equipment

Product Description

What is PCB and its types?

Printed circuit board (PCB) will appear in almost every electronic device. If there are Electronic Components in a certain kind of equipment, they are also mounted on custom pcb fabrications of various sizes. In addition to fixing various Electronic Components, the main function of the PCB is to provide the electrical connection of the upper parts. As electronic devices become more and more complex, more and more parts are needed, and the circuits and parts on the PCB are becoming more and more dense.

There are no parts on the standard PCB, and it is often called "Printed WiringBoard (PWB)".

The base plate of the board itself is made of insulating and heat-insulating materials that are not easy to bend. The small circuit material that can be seen on the surface is copper foil. The copper foil was originally covered on the entire board, but part of it was etched away during the custom pcb fabrication process, and the remaining part became a small mesh. Line up. These lines are called conductors (conductorpattern) or wiring, and are used to provide circuit connections for parts on the PCB.

In order to fix the parts on the PCB, we solder their pins directly on the wiring. On the most basic PCB (single panel), the parts are concentrated on one side, and the wires are concentrated on the other side. In this way, we need to make holes in the board so that the pins can pass through the board to the other side, so the pins of the parts are welded to the other side. Because of this, the front and back sides of the PCB are respectively called the component side (ComponentSide) and the solder side (SolderSide).

If there are some parts on the PCB that need to be removed or reinstalled after the production is completed, then the socket will be used when installing the part. Since the socket is directly welded to the board, the parts can be disassembled and assembled at will.

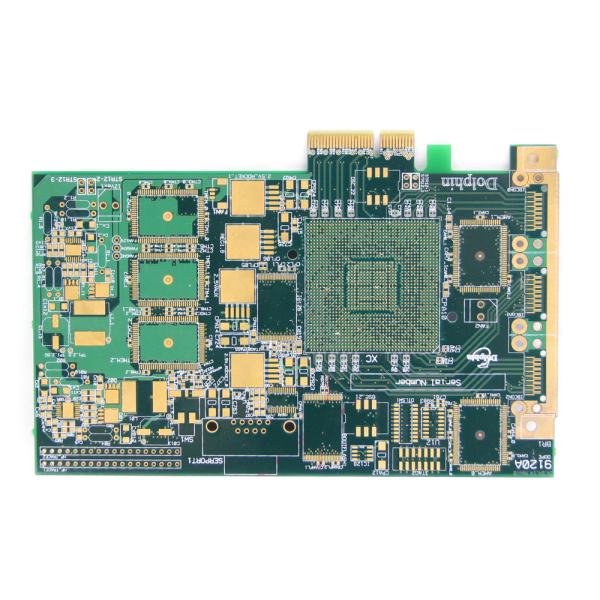

If you want to connect two PCBs to each other, generally we will use the edge connector commonly known as "golden finger". There are many exposed copper pads on the golden fingers, which are actually part of the PCB wiring. Usually when connecting, we insert the golden finger on one PCB into the appropriate slot on the other PCB (generally called the expansion slot Slot). In computers, display cards, sound cards or other similar interface cards are connected to the motherboard by golden fingers.

The green or brown on the PCB is the color of the solder mask. This layer is an insulating protective layer, which can protect the copper wire and prevent the parts from being welded to the wrong place. In addition, a layer of silkscreen will be printed on the solder mask. Usually words and symbols (mostly white) are printed on this to mark the position of each part on the board. The screen printing surface is also called the icon surface (legend).

Custom pcb fabrication etches the complex circuit copper wires between parts and parts on a PCB after careful and neat planning, and provides the main support for the installation and interconnection of Electronic Components. It is indispensable for all electronic products. The basic parts.

The printed circuit board is a flat plate made of non-conductive materials. The flat plate is usually designed with pre-drilled holes to install chips and other electronic components. The holes of SMT&Through-Hole Assembly help to electronically connect the pre-defined metal paths printed on the board. After the pins of the electronic components are passed through the PCB, they are then attached to the PCB with conductive metal welding rods. Form the circuit.

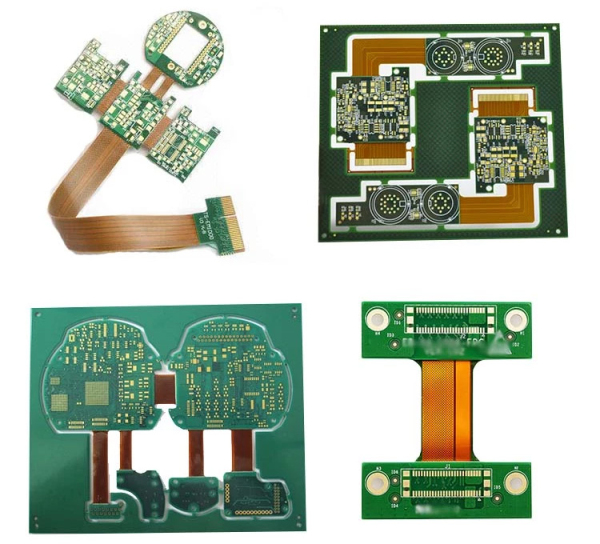

According to its application field, PCB can be divided into single-sided board, double-sided board, four-layer board or more, and High Quality PCB Fabrication Flex. Generally speaking, the more complex the functions of electronic products, the longer the loop distance, and the more the number of contact pins, the more layers the PCB requires, such as high-end consumer electronics, information and communication products, etc.; and soft boards are mainly used for needs. Among the winding products: such as notebook computers, cameras, car meters, etc.

Product Categories : Rigid-Flex Board > BVH PCB